Laser Scanners for Laser Welding

Laser Scanners for Laser Welding: Precision, Speed, and Reliability with ScannerMAX Optical Scanning Systems

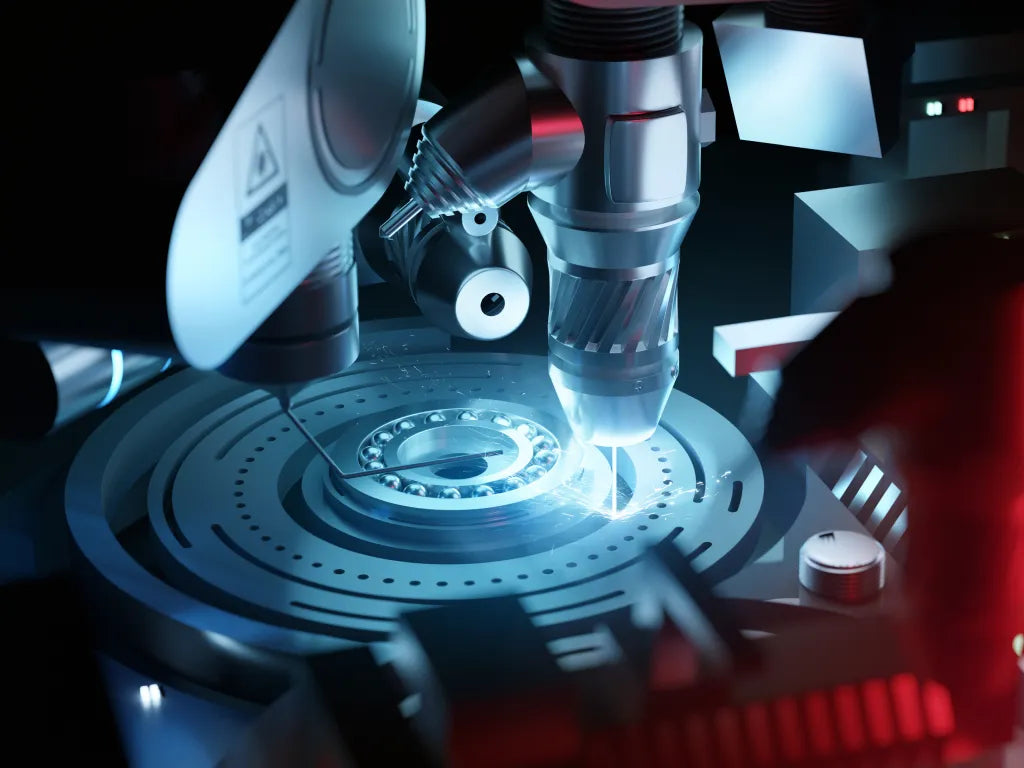

Enhancing Laser Welding with Advanced Scanning Technology

Laser welding has become a vital manufacturing process, requiring precision, speed, and stability to achieve strong, high-quality welds. A key factor in optimizing laser welding systems is the use of high-performance galvanometer-based laser scanners that deliver fast, accurate beam control with minimal heat generation.

ScannerMAX scanners are designed to meet these demands, offering stronger, cooler, and faster solutions that enhance laser welding efficiency, reduce operational costs, and improve final product quality.

Versatile Applications of ScannerMAX Scanners in Laser Welding

ScannerMAX scanners, powered by the Mach-DSP servo driver, support a wide range of laser welding applications, including:

- Spot Welding – Ultra-fast beam positioning for micro-welding applications

- Seam Welding – Continuous and precise scanning for extended welds

- Remote Welding – Large-field scanning for flexible automation

By combining high-performance scanning technology with digital servo control, manufacturers can achieve higher welding speeds, greater accuracy, and improved process stability.

The ScannerMAX Advantage for Laser Welding

- Durability & Strength – Reinforced rotors, stronger shafts, and high-performance bearings ensure long-lasting, high-speed operation in demanding industrial environments

- High-Speed Performance – Advanced magnetic circuit technology enables rapid beam positioning with minimal power consumption, reducing processing time and increasing efficiency

- Optimized Thermal Management – Low coil resistance and superior heat dissipation allow for cooler operation and extended lifespan, ensuring stable performance during long production runs

- Precision Control – Low-noise position sensors provide accurate, repeatable motion for clean, defect-free welds

- Advanced Mirror Coatings & Substrates – High reflectivity, thermal resistance, and durability accommodate extreme power levels in laser welding

- Seamless Digital Integration – The Mach-DSP servo driver supports XY2-100 digital command input for real-time, high-precision beam control

- User-Friendly Interface – PC-based graphical user interface enables performance fine-tuning, real-time monitoring, and multiple settings storage for optimized welding processes

Optimize Your Laser Welding System with ScannerMAX

Discover how our ScannerMAX scanners and Mach-DSP servo driver can enhance your laser welding applications.