Micromachining

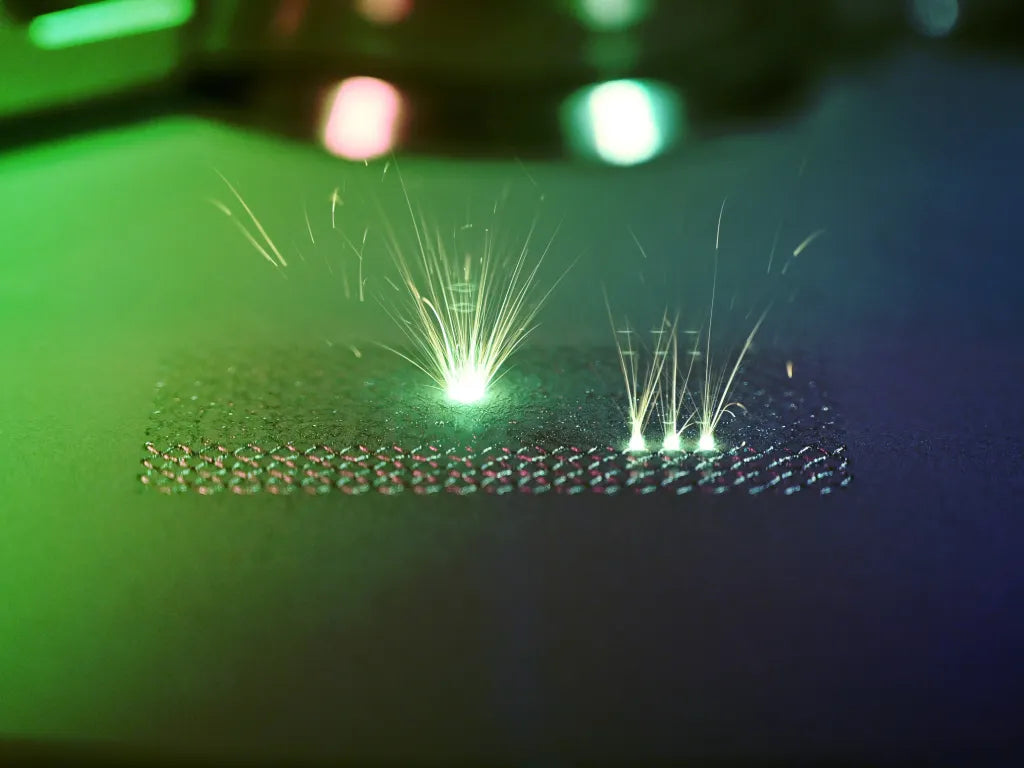

Micromachining with ScannerMAX: Precision, Speed, and Reliability

Unlock the Power of High-Performance Laser Scanning

Micromachining requires unmatched precision, speed, and thermal efficiency—three critical factors that define the ScannerMAX "Stronger, Cooler, Faster" advantage. Whether for industrial manufacturing, medical device fabrication, or semiconductor processing, ScannerMAX galvanometer-based optical scanners provide the ultra-fast, high-accuracy performance necessary to achieve superior results.

Applications in Micromachining using Optical Scanning Systems

- Micro-Cutting – High-precision laser cutting for microfabrication and industrial applications

- Micro-Scribing – Controlled material removal for semiconductors, glass, and thin films

- Micro-Marking – Permanent, high-resolution marking on metals, plastics, and medical devices

- Micro-Engraving – Detailed surface texturing for security printing and industrial applications

- Micro-Drilling – Precision drilling of micro-holes for aerospace, medical, and electronics

- Micro-Ablation – Selective material removal for structuring, cleaning, and surface modification

- Micro-Patterning – High-speed structuring for intricate micro-scale designs and optical elements

Why Choose ScannerMAX for Micromachining?

- Unparalleled speed and accuracy: Our high-performance galvanometers provide industry-leading scanning speeds, reducing cycle times and improving throughput

- Superior thermal management: Low coil resistance means minimal heat generation, ensuring stable operation and preventing thermal drift—crucial for high-precision micromachining applications

- Enhanced durability and stability: ScannerMAX scanners incorporate a stiffer rotor design with larger-diameter shafts and ceramic hybrid bearings, reducing wobble and jitter to maintain sub-micron accuracy

- Wide-angle scanning capability: With scanning angles up to 110 degrees optical, ScannerMAX solutions provide flexibility for a variety of micromachining tasks

Mach-DSP: Advanced Control for Micromachining Applications

To complement our high-performance scanners, the Mach-DSP servo driver provides state-of-the-art control for precise and repeatable micromachining operations. Designed for flexibility and high-speed processing, the Mach-DSP enables superior scanner performance through advanced servo tuning and real-time control capabilities.

Key Features of the Mach-DSP

- XY2-100 digital input support – Fully compatible with XY2-100 protocol, allowing seamless integration with laser marking and micromachining systems

- Four user-configurable tunings – Store and switch between four separate tuning profiles with different bandwidths and tuning laws for optimized performance

- Advanced servo algorithms – Supports PD, PID, PDF, and PDFF servo control laws, ensuring unmatched precision and stability

- PC-based graphical user interface – Provides real-time monitoring, adjustment, and analysis for fine-tuned system performance

- Compact and power-efficient design – Small footprint and low power consumption for seamless integration into existing micromachining systems

With Mach-DSP and ScannerMAX scanners working together, you gain the ultimate speed, accuracy, and flexibility to push the limits of micromachining performance.

ScannerMAX: Your Competitive Edge in Micromachining

With high-speed torque-to-inertia ratios, industry-leading thermal efficiency, and robust construction, ScannerMAX solutions are redefining micromachining performance. Whether you need precision cutting, scribing, marking, engraving, drilling, ablation, or patterning, our scanners ensure maximum efficiency with minimum heat and power consumption.

Elevate your micromachining process with ScannerMAX—where precision meets performance.