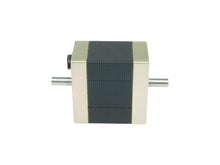

VRAD-1510

Price on request

Only available in volume orders of 100+

Description

The VRAD-1510 actuator is a small, galvanometer style, limited rotation Versatile Rotary Actuator Device featuring a magnetic spring return, wide-angle capability, and linear angle-versus-current profile. Suited for applications such as optical element positioning, fluid valve actuator, air damper/door actuator and optical beam chopper/shutter.

Features of the VRAD-1510 Series

- The VRAD-1510 feature a magnetic spring return, which provides torque in the direction that will restore the rotor to its central resting position.

- The high coil resistance allows for low power consumption, and access to two individual drive coils allows flexible single-supply unidirectional or bidirectional operation as well as dual-supply operation.

- In addition, each coil has a resistance of 28 ohms and an inductance of approximately 60 millihenry. The series combination of coils has only 56 ohms, yet nearly 3 times the inductance of a single coil, 175 millihenry at 1kHz.

- An internal rear shaft allows for use of an encoder or position sensor for closed loop operation.

The key innovation contained within our VRAD rotary actuators, is our patented stator design that uses a series of asymmetrical, interleaved laminations that are inexpensive to make, easy to assemble, and fit together in a way that prevents the introduction of air gaps to the motor’s magnetic field. By rethinking the stator design, we have developed a more versatile, compact and durable rotary actuator.

Specifications

| Rotation Angle (1): | +\- 45 Degrees |

| Torque Constant (2): | 1,500,00 Dyne*Centimeters per Ampere |

| Magnetic Spring Stiffness (3): | 10,700 Dyne*Centimeters per degree |

| Rotor Inertia: | 0.5 Gram*Centimeter2 |

| Natural Frequency(4): | 185Hz |

| Coil Resistance(5): | 56 Ohms (coils in series) |

| Coil Inductance(5): | 175mH at 1kHz (coils in series) |

| Maximum current(6): | 2.0 Amp per coil |

| Angle vs. Current Linearity: | 95% over +/-45 degrees peak-to-peak |

| Angle vs. Current Sensitivity(7): | 7mA per degree (coils in series) |

| Temperature coefficient of sensitivity: | +0.14% per °C |

| Angular position hysteresis: | +/- 1 Mechanical degrees maximum |

| Maximum internal temperature(8): | 80°C |

| Thermal resistance with heatsink(9): | 7.6°C per Watt |

| Thermal resistance without heatsink: | 12°C per Watt |

| DC Power at +/-15 degrees: | 0.64 Watts (6V series; 3V parallel) |

| DC Power at +/-30 degrees: | 2.57 Watts (12V series; 6V parallel) |

| DC Power at +/-45 degrees: | 5.78 Watts (18V series; 9V parallel) |

| DC Power at +/-60 degrees: | 10.28 Watts (24V series; 12V parallel) |

| Dielectric Strength: | 1000 VRMS |

| Life cycles(10): | 1010 Cycles |

| Mass: | 180 Grams |

NOTES

- There is no mechanical stop mechanism preventing further rotation, and the actuator may be used with angles well over +/- 60 mechanical degrees with some sacrifice in angle-versus-current linearity.

- Torque Factor depends on the shaft rotation angle.

- Magnetic spring stiffness depends on the shaft rotation angle and the model of the actuator and is easily customizable.

- Since Magnetic Spring Stiffness depends on angle, Natural Frequency also has some minor dependence on angle. Natural frequency is thus specified for small angles.

- Coil resistance and inductance depend on whether coils are connected in series, in parallel, or used independently.

- This is a limitation imposed by the connector and it assumes that AWG #24 wire is crimped into each terminal. This current is de-rated to 0.5A if AWG #30 wire is crimped instead.

- Angle vs. Current operation assumes that there is no static load and that the actuator is merely used to move a flag, mirror, or other element suspended from the actuator shaft.

- Maximum internal temperature of the actuator for commercial-grade units. Industrial-grade units are available whose temperature can exceed 100°C.

- Heat sink must be clamped around the actuator to meet the specification above.

- Life cycles are only limited by bearing life. Bearings are high quality disk drive grade.

Specifications are at a temperature of 25° C. All mechanical and electrical specifications are +/-10%.